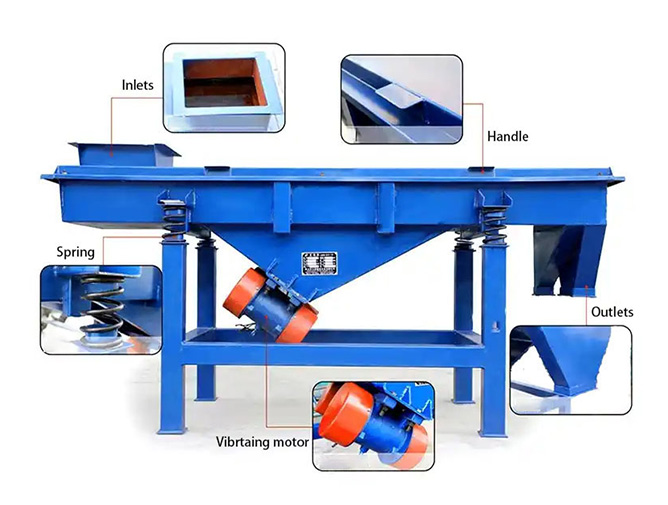

Running Machinery linear vibrating screen uses vibration motor excitation as the vibration source to throw the material on the screen and move forward in a straight line at the same time. The material evenly enters the feed port of the screening machine from the feeder and generates data through the multi-layer screen. The above- and under-sieve materials of various specifications are discharged from their respective outlets. It has low energy consumption, high output, simple structure, easy maintenance, fully enclosed structure, no dust spillage, automatic discharge, and is more suitable for assembly line operations.

① Suitable for rough screening, grading, impurity removal and large processing capacity of general materials;

② Simple structure, tight sealing, low noise, easy maintenance and low energy consumption;

③ One or more layers of screens can be installed;

④ Two vibration motors are used as excitation sources, and the processing effect is obvious;

⑤ The power layout can be adjusted appropriately according to customer needs to adapt to corresponding production conditions;

⑥ Mainly suitable for mining, metallurgy, abrasives, building materials and other industries.

1. Chemical Industry: Screen plastic pellets, resins, and granules for precise particle sizing and impurity removal.

2. Food Processing: Separate sugar, salt, grains, and spices to ensure uniform quality and hygiene.

3. Mining & Aggregates: Classify ores, coal, sand, and crushed stones efficiently in high-capacity operations.

4. Metallurgy: Grade metal powders, alloy chips, or slag for material recycling and refining.

5. Pharmaceuticals: Sieve granules, powders, and raw materials under controlled, dust-free conditions.

6. Agriculture: Clean seeds, grains, or fertilizers by removing debris and oversized particles.

7. Building Materials: Screen cement, sand, gypsum, or dry mortar for consistent grading.

8. Recycling: Sort plastics, glass fragments, or e-waste to enhance material purity and recovery rates.

|

Model |

Particle Size(mm) |

Voltage(v) |

Power(kw) |

Amplitude(mm) |

Number Of Layers |

|

RNZX-520 |

≥0.3 |

380 |

0.37-0.55 |

2-4 |

1-6 |

|

RNZX-525 |

≥0.3 |

380 |

|||

|

RNZX-1025 |

≥0.3 |

380 |

0.75-1.1 |

||

|

RNZX-1030 |

≥0.3 |

380 |

1.1-1.5 |

3-5 |

|

|

RNZX-1225 |

≥0.3 |

380 |

|||

|

RNZX-1230 |

≥0.3 |

380 |

1.5-2.2 |

||

|

RNZX-1530 |

≥0.3 |

380 |

|||

|

RNZX-1540 |

≥0.3 |

380 |

3-4.4 |

3-7 |

|

|

RNZX-1840 |

≥0.3 |

380 |

4.4-7.4 |

||

|

RNZX-2050 |

≥0.3 |

380 |

7.4-11 |

The rotary vibrating screen uses weights (unbalanced weights) installed at the upper and lower ends of the vibration motor to...

Learn MoreThe screen of this equipment is cylindrical and is placed in the body. After the material passes through the screw conveyor...

Learn MoreThe fully enclosed dust-free ton bag feeding station has a simple structure and a high degree of automation...

Learn MoreThis product can mix powder with powder, powder with granules, especially materials with widely different specific gravity...

Learn MoreFrom the perspective of the motion trajectory of the screen machine's shaking body, that is, the screen box...

Learn More